Here's a quick way to cut a dado on a table saw. It takes a combination saw blade and two spacers, which establish the two sides of the dado. The material between the sides is wasted out.

Spacer Thickness: The key to making this work is the thickness of the spacers. The first spacer matches the thickness of the workpiece that fits into the dado. (A scrap piece from the project works just fine.) And the second spacer equals the thickness of the blade. (I use a piece of 1/8" hardboard with a single strip of masking tape.)

First Side: Start by clamping one spacer (the scrap from the project) to the rip fence. Then position the fence so the saw blade aligns with the near side of the dado (see detail 'a').

After locking the fence in place, butt the workpiece against the spacer and use the miter gauge to push it through the blade. Note: You can use this same technique for cutting grooves.

Keep in mind that the spacers need to be the same length as the fence.

Second Side: Keeping the rip fence in the same position, replace the first spacer with one that matches the thickness of the blade, as shown above. With this spacer clamped in place, it's just a matter of making a second pass (see detail 'b').

Remove Waste: Simply "nibble" away the waste by making as many passes as needed (see detail 'b').

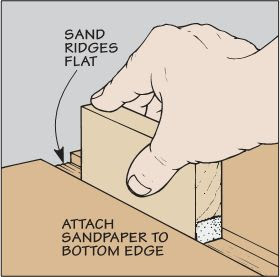

Ridges: If the end of the dado is going to be exposed, you may want to remove the ridges left by the combination blade. For a handy way to do this, take a look at the drawing at left.

No comments:

Post a Comment