Recently while turning an intricate spindle, my chisel caught the workpiece and tore out a chunk of wood. Rather than discard the turning, I came up with a simple technique to repair the damage.

First I use a parting tool to turn down the damaged area to a consistent diameter, as shown in Figs.1 and 1a.

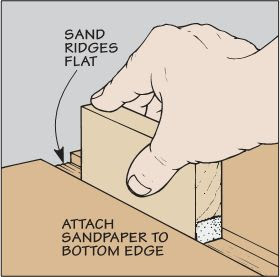

Next, I select a block of wood with similar color and grain as the spindle that’s being repaired. The length of the block should match the width of the area that was turned down on the spindle. Then I drill a hole in the center of the block to match the diameter of the area to be repaired.

Next I cut the block in half on a band saw (or split with a chisel) and glue in place around the spindle, as shown in Figs.2 and 2a. Once the glue dries, the spindle can be returned. If you take the time to carefully match the grain of the block with the spindle, the repair will be hardly noticeable.